DEVELOPMENTS IN DOMESTIC TECHNOLOGY

입력 2019.08.19 (15:05)

수정 2019.08.19 (16:19)

읽어주기 기능은 크롬기반의

브라우저에서만 사용하실 수 있습니다.

[Anchor Lead]

The South Korean government is stepping up efforts to buffer the nation's industries from repercussions of Japan's export restrictions. On August 20, it will launch a task force with missions to help businesses hit by Japan's export curbs. But domestic businesses have also been hard at work to enhance competitiveness on their own. Next, we will bring you stories of companies that are small in size but strong in technology.

[Pkg]

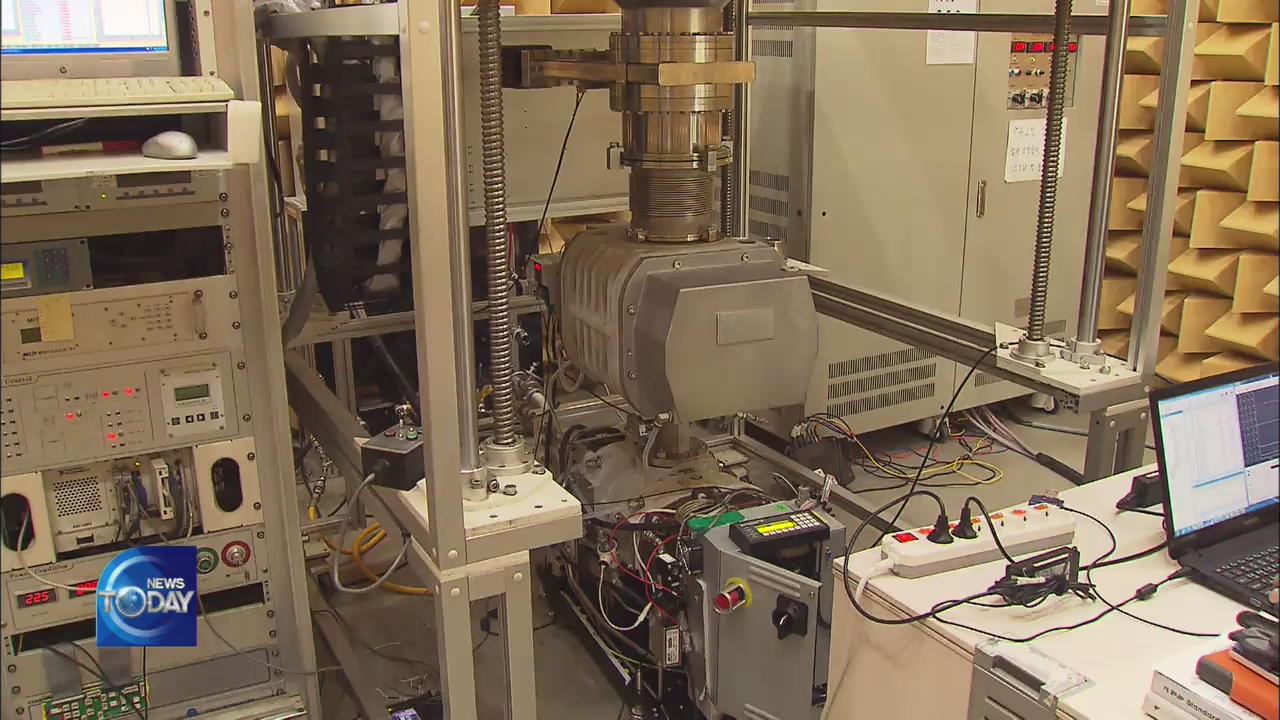

At this busy factory... Workers ceaselessly assemble products, which are then transported by automated conveyors. This company's vacuum pumps are indispensable in producing semiconductors or displays as their vacuum state determines the quality of the end products. 95 percent of components comprising the pumps are domestically produced. So this firm is facing little repercussions of Tokyo's export restrictions. As a result of continued, devoted efforts, the company successfully developed its own technology 16 years ago, breaking a monopoly held by Japan and Europe.

[Soundbite] OH HEUNG-SIK(PRES., VACUUM PUMP COMPANY) : "I started the business in 2002, determined to develop a domestic technology. My company now holds a 20 percent share in the market for vacuum pumps used in semiconductors."

Used at a steel mill, this decelerator heightens the power of equipment to increase pressure on iron plates. It is fully manufactured by a small, domestic company. The secret to this home-grown technology was the development of a gear. The essential part used to be imported from Japan in the past. However, with the advancement of local technology, Korea now even exports it to Tokyo. The R&D was made easier thanks to cooperation from a conglomerate that purchases the device. By teaming up with the smaller firm, the larger company is in turn able to spend 80 percent less compared to using imports.

[Soundbite] CHUNG DAE-SUNG(PRES., MACHINERY COMPANY) : "From designing to manufacturing, my company is fully capable of domestically producing the device, which used to be imported from Japan."

These small but competitive companies have been able to develop their own excellent technologies, with strong determination to challenge and overcome hardships.

The South Korean government is stepping up efforts to buffer the nation's industries from repercussions of Japan's export restrictions. On August 20, it will launch a task force with missions to help businesses hit by Japan's export curbs. But domestic businesses have also been hard at work to enhance competitiveness on their own. Next, we will bring you stories of companies that are small in size but strong in technology.

[Pkg]

At this busy factory... Workers ceaselessly assemble products, which are then transported by automated conveyors. This company's vacuum pumps are indispensable in producing semiconductors or displays as their vacuum state determines the quality of the end products. 95 percent of components comprising the pumps are domestically produced. So this firm is facing little repercussions of Tokyo's export restrictions. As a result of continued, devoted efforts, the company successfully developed its own technology 16 years ago, breaking a monopoly held by Japan and Europe.

[Soundbite] OH HEUNG-SIK(PRES., VACUUM PUMP COMPANY) : "I started the business in 2002, determined to develop a domestic technology. My company now holds a 20 percent share in the market for vacuum pumps used in semiconductors."

Used at a steel mill, this decelerator heightens the power of equipment to increase pressure on iron plates. It is fully manufactured by a small, domestic company. The secret to this home-grown technology was the development of a gear. The essential part used to be imported from Japan in the past. However, with the advancement of local technology, Korea now even exports it to Tokyo. The R&D was made easier thanks to cooperation from a conglomerate that purchases the device. By teaming up with the smaller firm, the larger company is in turn able to spend 80 percent less compared to using imports.

[Soundbite] CHUNG DAE-SUNG(PRES., MACHINERY COMPANY) : "From designing to manufacturing, my company is fully capable of domestically producing the device, which used to be imported from Japan."

These small but competitive companies have been able to develop their own excellent technologies, with strong determination to challenge and overcome hardships.

■ 제보하기

▷ 카카오톡 : 'KBS제보' 검색, 채널 추가

▷ 전화 : 02-781-1234, 4444

▷ 이메일 : kbs1234@kbs.co.kr

▷ 유튜브, 네이버, 카카오에서도 KBS뉴스를 구독해주세요!

- DEVELOPMENTS IN DOMESTIC TECHNOLOGY

-

- 입력 2019-08-19 15:02:29

- 수정2019-08-19 16:19:30

[Anchor Lead]

The South Korean government is stepping up efforts to buffer the nation's industries from repercussions of Japan's export restrictions. On August 20, it will launch a task force with missions to help businesses hit by Japan's export curbs. But domestic businesses have also been hard at work to enhance competitiveness on their own. Next, we will bring you stories of companies that are small in size but strong in technology.

[Pkg]

At this busy factory... Workers ceaselessly assemble products, which are then transported by automated conveyors. This company's vacuum pumps are indispensable in producing semiconductors or displays as their vacuum state determines the quality of the end products. 95 percent of components comprising the pumps are domestically produced. So this firm is facing little repercussions of Tokyo's export restrictions. As a result of continued, devoted efforts, the company successfully developed its own technology 16 years ago, breaking a monopoly held by Japan and Europe.

[Soundbite] OH HEUNG-SIK(PRES., VACUUM PUMP COMPANY) : "I started the business in 2002, determined to develop a domestic technology. My company now holds a 20 percent share in the market for vacuum pumps used in semiconductors."

Used at a steel mill, this decelerator heightens the power of equipment to increase pressure on iron plates. It is fully manufactured by a small, domestic company. The secret to this home-grown technology was the development of a gear. The essential part used to be imported from Japan in the past. However, with the advancement of local technology, Korea now even exports it to Tokyo. The R&D was made easier thanks to cooperation from a conglomerate that purchases the device. By teaming up with the smaller firm, the larger company is in turn able to spend 80 percent less compared to using imports.

[Soundbite] CHUNG DAE-SUNG(PRES., MACHINERY COMPANY) : "From designing to manufacturing, my company is fully capable of domestically producing the device, which used to be imported from Japan."

These small but competitive companies have been able to develop their own excellent technologies, with strong determination to challenge and overcome hardships.

The South Korean government is stepping up efforts to buffer the nation's industries from repercussions of Japan's export restrictions. On August 20, it will launch a task force with missions to help businesses hit by Japan's export curbs. But domestic businesses have also been hard at work to enhance competitiveness on their own. Next, we will bring you stories of companies that are small in size but strong in technology.

[Pkg]

At this busy factory... Workers ceaselessly assemble products, which are then transported by automated conveyors. This company's vacuum pumps are indispensable in producing semiconductors or displays as their vacuum state determines the quality of the end products. 95 percent of components comprising the pumps are domestically produced. So this firm is facing little repercussions of Tokyo's export restrictions. As a result of continued, devoted efforts, the company successfully developed its own technology 16 years ago, breaking a monopoly held by Japan and Europe.

[Soundbite] OH HEUNG-SIK(PRES., VACUUM PUMP COMPANY) : "I started the business in 2002, determined to develop a domestic technology. My company now holds a 20 percent share in the market for vacuum pumps used in semiconductors."

Used at a steel mill, this decelerator heightens the power of equipment to increase pressure on iron plates. It is fully manufactured by a small, domestic company. The secret to this home-grown technology was the development of a gear. The essential part used to be imported from Japan in the past. However, with the advancement of local technology, Korea now even exports it to Tokyo. The R&D was made easier thanks to cooperation from a conglomerate that purchases the device. By teaming up with the smaller firm, the larger company is in turn able to spend 80 percent less compared to using imports.

[Soundbite] CHUNG DAE-SUNG(PRES., MACHINERY COMPANY) : "From designing to manufacturing, my company is fully capable of domestically producing the device, which used to be imported from Japan."

These small but competitive companies have been able to develop their own excellent technologies, with strong determination to challenge and overcome hardships.

이 기사가 좋으셨다면

-

좋아요

0

-

응원해요

0

-

후속 원해요

0

이 기사에 대한 의견을 남겨주세요.