PROGRESS IN PRODUCING LOCAL PARTS

입력 2021.07.01 (15:36)

수정 2021.07.01 (16:46)

읽어주기 기능은 크롬기반의

브라우저에서만 사용하실 수 있습니다.

[Anchor Lead]

It's been two years since Japan imposed export restrictions on Korea. This has presented Korean businesses with new opportunities by making them realize the importance of locally producing materials, components and equipment. But there are still challenges ahead.

[Pkg]

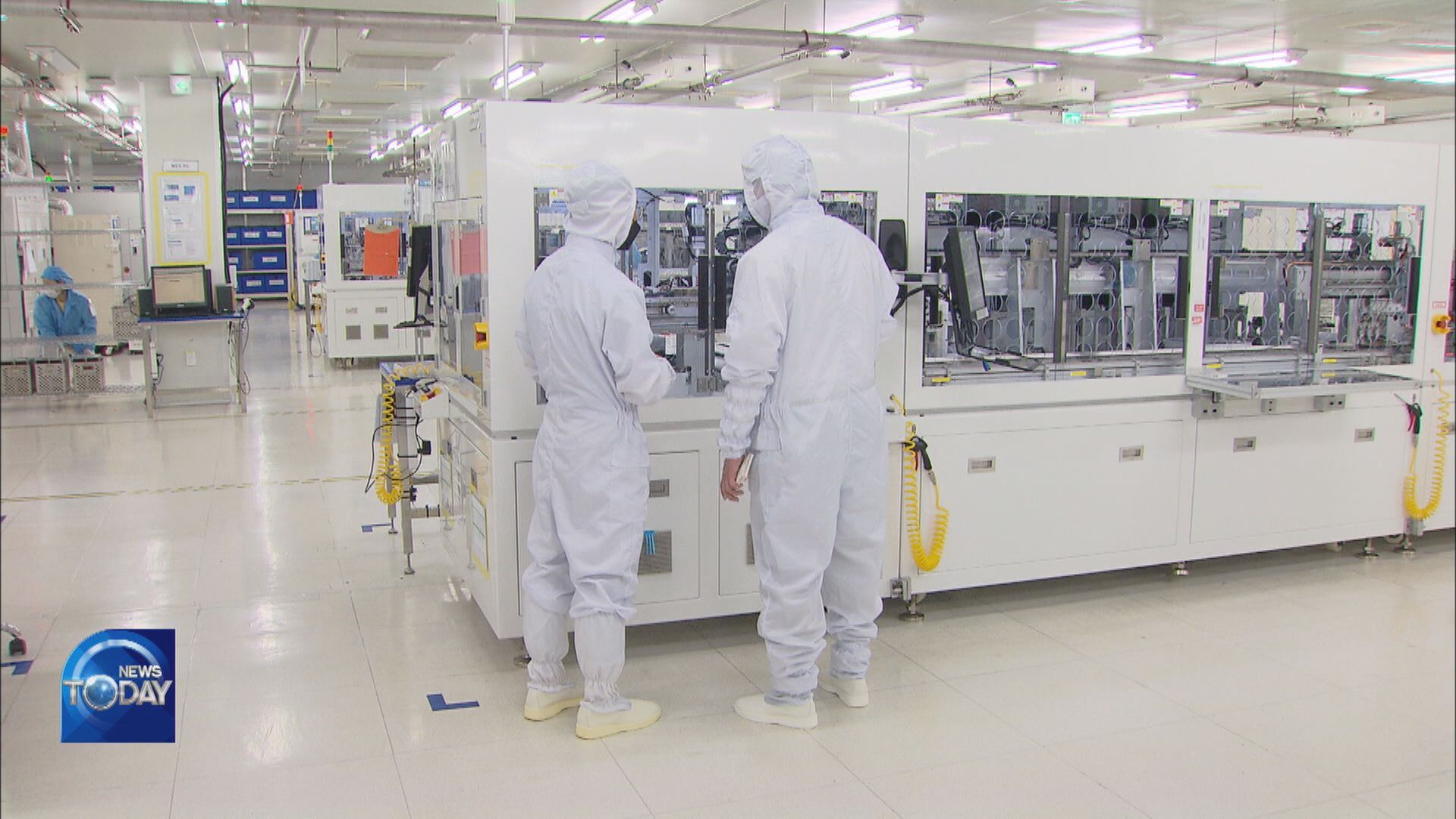

This company used to produce industrial hydrofluoric acid. Recently it succeeded in developing high-purity hydrogen fluoride for electronic chips. It plans to release its new product soon. After Japan imposed export restrictions on Korea, local businesses turned the crisis into opportunity.

[Soundbite] Huh Kuk(CEO of hydrogen fluoride producing firm) : "After Japan imposed restrictions, the Korean government proposed solutions for us, which inspired us to develop our own technologies and commercialize them. That's how we developed high-purity hydrogen fluoride."

Thanks to efforts to localize core materials, Korea's imports of hydrogen fluoride from Japan have plummeted. Reliance on Japanese materials, components and equipment dropped to the lowest level to date. The industrial sector is also undergoing transformation. As more and more domestic firms can produce materials and components that can replace Japanese ones, Korean businesses are building a collaboration network. This components maker has signed a supply contract with a domestic conglomerate.

[Soundbite] Park Sang-koo(Staff at firm producing heat products) : "As Japanese products are no longer imported, domestic conglomerates are looking for suppliers in Korea. Small firms like ours have more business opportunities these days."

Stable supply of locally produced materials led to the development of more competitive technologies.

[Soundbite] Hwang Ho-seok(Staff at semiconductor firm) : "We've been learning about new technologies, developing our own and applying for new patents to secure a competitive edge."

However, reliance on Japan remains high when it comes to advanced materials and equipment. As a result, when Seoul's exports expand, its trade deficit with Tokyo grows as well.

[Soundbite] Lee Jun(Korea Institute for Industrial Economics and Trade) : "Products that can be replaced with domestic ones account for a small share in Korea's trade deficit with Japan. More time is needed to overhaul Korea's imports from Japan."

It's been two years since Japan imposed export controls on South Korea. It's time to overhaul the very foundation of the Korean economy.

It's been two years since Japan imposed export restrictions on Korea. This has presented Korean businesses with new opportunities by making them realize the importance of locally producing materials, components and equipment. But there are still challenges ahead.

[Pkg]

This company used to produce industrial hydrofluoric acid. Recently it succeeded in developing high-purity hydrogen fluoride for electronic chips. It plans to release its new product soon. After Japan imposed export restrictions on Korea, local businesses turned the crisis into opportunity.

[Soundbite] Huh Kuk(CEO of hydrogen fluoride producing firm) : "After Japan imposed restrictions, the Korean government proposed solutions for us, which inspired us to develop our own technologies and commercialize them. That's how we developed high-purity hydrogen fluoride."

Thanks to efforts to localize core materials, Korea's imports of hydrogen fluoride from Japan have plummeted. Reliance on Japanese materials, components and equipment dropped to the lowest level to date. The industrial sector is also undergoing transformation. As more and more domestic firms can produce materials and components that can replace Japanese ones, Korean businesses are building a collaboration network. This components maker has signed a supply contract with a domestic conglomerate.

[Soundbite] Park Sang-koo(Staff at firm producing heat products) : "As Japanese products are no longer imported, domestic conglomerates are looking for suppliers in Korea. Small firms like ours have more business opportunities these days."

Stable supply of locally produced materials led to the development of more competitive technologies.

[Soundbite] Hwang Ho-seok(Staff at semiconductor firm) : "We've been learning about new technologies, developing our own and applying for new patents to secure a competitive edge."

However, reliance on Japan remains high when it comes to advanced materials and equipment. As a result, when Seoul's exports expand, its trade deficit with Tokyo grows as well.

[Soundbite] Lee Jun(Korea Institute for Industrial Economics and Trade) : "Products that can be replaced with domestic ones account for a small share in Korea's trade deficit with Japan. More time is needed to overhaul Korea's imports from Japan."

It's been two years since Japan imposed export controls on South Korea. It's time to overhaul the very foundation of the Korean economy.

■ 제보하기

▷ 카카오톡 : 'KBS제보' 검색, 채널 추가

▷ 전화 : 02-781-1234, 4444

▷ 이메일 : kbs1234@kbs.co.kr

▷ 유튜브, 네이버, 카카오에서도 KBS뉴스를 구독해주세요!

- PROGRESS IN PRODUCING LOCAL PARTS

-

- 입력 2021-07-01 15:36:18

- 수정2021-07-01 16:46:40

[Anchor Lead]

It's been two years since Japan imposed export restrictions on Korea. This has presented Korean businesses with new opportunities by making them realize the importance of locally producing materials, components and equipment. But there are still challenges ahead.

[Pkg]

This company used to produce industrial hydrofluoric acid. Recently it succeeded in developing high-purity hydrogen fluoride for electronic chips. It plans to release its new product soon. After Japan imposed export restrictions on Korea, local businesses turned the crisis into opportunity.

[Soundbite] Huh Kuk(CEO of hydrogen fluoride producing firm) : "After Japan imposed restrictions, the Korean government proposed solutions for us, which inspired us to develop our own technologies and commercialize them. That's how we developed high-purity hydrogen fluoride."

Thanks to efforts to localize core materials, Korea's imports of hydrogen fluoride from Japan have plummeted. Reliance on Japanese materials, components and equipment dropped to the lowest level to date. The industrial sector is also undergoing transformation. As more and more domestic firms can produce materials and components that can replace Japanese ones, Korean businesses are building a collaboration network. This components maker has signed a supply contract with a domestic conglomerate.

[Soundbite] Park Sang-koo(Staff at firm producing heat products) : "As Japanese products are no longer imported, domestic conglomerates are looking for suppliers in Korea. Small firms like ours have more business opportunities these days."

Stable supply of locally produced materials led to the development of more competitive technologies.

[Soundbite] Hwang Ho-seok(Staff at semiconductor firm) : "We've been learning about new technologies, developing our own and applying for new patents to secure a competitive edge."

However, reliance on Japan remains high when it comes to advanced materials and equipment. As a result, when Seoul's exports expand, its trade deficit with Tokyo grows as well.

[Soundbite] Lee Jun(Korea Institute for Industrial Economics and Trade) : "Products that can be replaced with domestic ones account for a small share in Korea's trade deficit with Japan. More time is needed to overhaul Korea's imports from Japan."

It's been two years since Japan imposed export controls on South Korea. It's time to overhaul the very foundation of the Korean economy.

It's been two years since Japan imposed export restrictions on Korea. This has presented Korean businesses with new opportunities by making them realize the importance of locally producing materials, components and equipment. But there are still challenges ahead.

[Pkg]

This company used to produce industrial hydrofluoric acid. Recently it succeeded in developing high-purity hydrogen fluoride for electronic chips. It plans to release its new product soon. After Japan imposed export restrictions on Korea, local businesses turned the crisis into opportunity.

[Soundbite] Huh Kuk(CEO of hydrogen fluoride producing firm) : "After Japan imposed restrictions, the Korean government proposed solutions for us, which inspired us to develop our own technologies and commercialize them. That's how we developed high-purity hydrogen fluoride."

Thanks to efforts to localize core materials, Korea's imports of hydrogen fluoride from Japan have plummeted. Reliance on Japanese materials, components and equipment dropped to the lowest level to date. The industrial sector is also undergoing transformation. As more and more domestic firms can produce materials and components that can replace Japanese ones, Korean businesses are building a collaboration network. This components maker has signed a supply contract with a domestic conglomerate.

[Soundbite] Park Sang-koo(Staff at firm producing heat products) : "As Japanese products are no longer imported, domestic conglomerates are looking for suppliers in Korea. Small firms like ours have more business opportunities these days."

Stable supply of locally produced materials led to the development of more competitive technologies.

[Soundbite] Hwang Ho-seok(Staff at semiconductor firm) : "We've been learning about new technologies, developing our own and applying for new patents to secure a competitive edge."

However, reliance on Japan remains high when it comes to advanced materials and equipment. As a result, when Seoul's exports expand, its trade deficit with Tokyo grows as well.

[Soundbite] Lee Jun(Korea Institute for Industrial Economics and Trade) : "Products that can be replaced with domestic ones account for a small share in Korea's trade deficit with Japan. More time is needed to overhaul Korea's imports from Japan."

It's been two years since Japan imposed export controls on South Korea. It's time to overhaul the very foundation of the Korean economy.

이 기사가 좋으셨다면

-

좋아요

0

-

응원해요

0

-

후속 원해요

0

이 기사에 대한 의견을 남겨주세요.