JAPAN'S EXPORT CONTROLS & DOMESTIC DEVELOPMENT

입력 2020.01.06 (15:53)

수정 2020.01.06 (16:46)

읽어주기 기능은 크롬기반의

브라우저에서만 사용하실 수 있습니다.

[Anchor Lead]

It has been six months since Japan imposed export controls on Korea. Now initially, there were concerns that Korean semiconductor makers would suffer setbacks, but it seems they havn't been hit as badly as it was first thought. Better yet, Japan's export curbs prompted Korea to diversify the country's materials and parts import sources and rely less on Japan.

[Pkg]

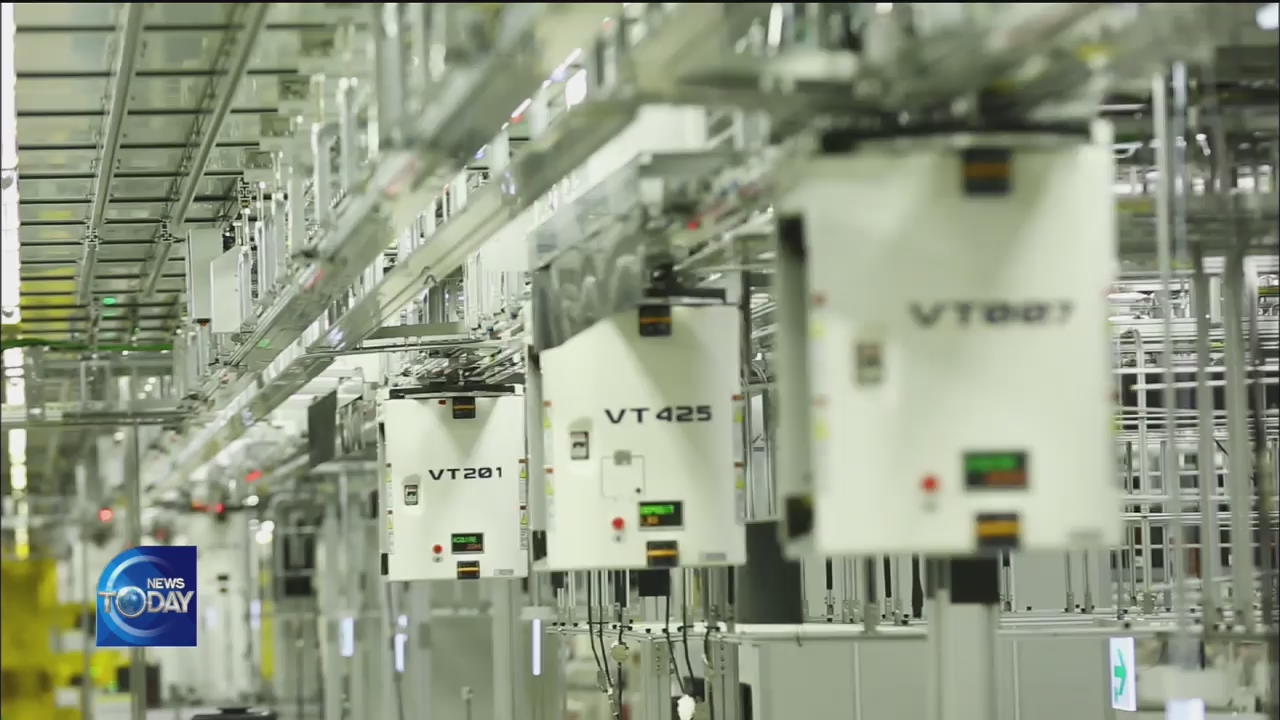

Employees in white cleanroom garments are busy conducting a test. They're running the final quality control test to see if the hydrogen fluoride is more than 99.99% pure before it's shipped out. Hydrogen fluoride is one of the three products that were subjected to Japan's export restrictions. It's a key material used in etching silicon wafers and removing impurities from them. Korea depended on Japan to meet two-thirds of its demand as it was more economical. But a Korean hydrogen fluoride manufacturer promptly increased its production lines to successfully replace the Japanese imports with local products in just six months.

[Soundbite] KANG BYEONG-CHANG(CEO, HYDROGEN FLUORIDE MANUFACTURING COMPANY) : "The locally produced hydrogen fluoride received good marks in the quality assessment late last year. Now we can start supplying the products."

Photoresist is an essential material used in engraving semiconductor circuits on silicon wafers. This material caused the greatest concern since it was the item with the highest dependency on Japan and it was projected to take more than a year to develop an alternate product. But contrary to such concern, it was the first material that Korea was able to source elsewhere. The country was able to quickly secure an alternate import source from Belgium. Global corporations are working to produce the material locally. Polyimide used in making flexible displays was not an issue from the beginning since local production had been underway before Japan's export restriction. Industry insiders are puzzled as to why Japan placed curbs on it in the first place. The general consensus is that Korean firms suffered practically no losses for the past six months since Japan's export control.

[Soundbite] KIM DONG-WON(KB SECURITIES) : "Japan's export controls motivated Korea to develop its own products, thereby helping Korea to gain mid-to-long term competitiveness."

Over the next five years, the Korean government plans to produce locally or diversify import sources for 100 items that are highly dependent on Japan. Subsequently, Seoul will invest more than two trillion won, 2.5 times more than last year, in the materials, parts, and equipment industries this year.

It has been six months since Japan imposed export controls on Korea. Now initially, there were concerns that Korean semiconductor makers would suffer setbacks, but it seems they havn't been hit as badly as it was first thought. Better yet, Japan's export curbs prompted Korea to diversify the country's materials and parts import sources and rely less on Japan.

[Pkg]

Employees in white cleanroom garments are busy conducting a test. They're running the final quality control test to see if the hydrogen fluoride is more than 99.99% pure before it's shipped out. Hydrogen fluoride is one of the three products that were subjected to Japan's export restrictions. It's a key material used in etching silicon wafers and removing impurities from them. Korea depended on Japan to meet two-thirds of its demand as it was more economical. But a Korean hydrogen fluoride manufacturer promptly increased its production lines to successfully replace the Japanese imports with local products in just six months.

[Soundbite] KANG BYEONG-CHANG(CEO, HYDROGEN FLUORIDE MANUFACTURING COMPANY) : "The locally produced hydrogen fluoride received good marks in the quality assessment late last year. Now we can start supplying the products."

Photoresist is an essential material used in engraving semiconductor circuits on silicon wafers. This material caused the greatest concern since it was the item with the highest dependency on Japan and it was projected to take more than a year to develop an alternate product. But contrary to such concern, it was the first material that Korea was able to source elsewhere. The country was able to quickly secure an alternate import source from Belgium. Global corporations are working to produce the material locally. Polyimide used in making flexible displays was not an issue from the beginning since local production had been underway before Japan's export restriction. Industry insiders are puzzled as to why Japan placed curbs on it in the first place. The general consensus is that Korean firms suffered practically no losses for the past six months since Japan's export control.

[Soundbite] KIM DONG-WON(KB SECURITIES) : "Japan's export controls motivated Korea to develop its own products, thereby helping Korea to gain mid-to-long term competitiveness."

Over the next five years, the Korean government plans to produce locally or diversify import sources for 100 items that are highly dependent on Japan. Subsequently, Seoul will invest more than two trillion won, 2.5 times more than last year, in the materials, parts, and equipment industries this year.

■ 제보하기

▷ 카카오톡 : 'KBS제보' 검색, 채널 추가

▷ 전화 : 02-781-1234, 4444

▷ 이메일 : kbs1234@kbs.co.kr

▷ 유튜브, 네이버, 카카오에서도 KBS뉴스를 구독해주세요!

- JAPAN'S EXPORT CONTROLS & DOMESTIC DEVELOPMENT

-

- 입력 2020-01-06 15:14:56

- 수정2020-01-06 16:46:05

[Anchor Lead]

It has been six months since Japan imposed export controls on Korea. Now initially, there were concerns that Korean semiconductor makers would suffer setbacks, but it seems they havn't been hit as badly as it was first thought. Better yet, Japan's export curbs prompted Korea to diversify the country's materials and parts import sources and rely less on Japan.

[Pkg]

Employees in white cleanroom garments are busy conducting a test. They're running the final quality control test to see if the hydrogen fluoride is more than 99.99% pure before it's shipped out. Hydrogen fluoride is one of the three products that were subjected to Japan's export restrictions. It's a key material used in etching silicon wafers and removing impurities from them. Korea depended on Japan to meet two-thirds of its demand as it was more economical. But a Korean hydrogen fluoride manufacturer promptly increased its production lines to successfully replace the Japanese imports with local products in just six months.

[Soundbite] KANG BYEONG-CHANG(CEO, HYDROGEN FLUORIDE MANUFACTURING COMPANY) : "The locally produced hydrogen fluoride received good marks in the quality assessment late last year. Now we can start supplying the products."

Photoresist is an essential material used in engraving semiconductor circuits on silicon wafers. This material caused the greatest concern since it was the item with the highest dependency on Japan and it was projected to take more than a year to develop an alternate product. But contrary to such concern, it was the first material that Korea was able to source elsewhere. The country was able to quickly secure an alternate import source from Belgium. Global corporations are working to produce the material locally. Polyimide used in making flexible displays was not an issue from the beginning since local production had been underway before Japan's export restriction. Industry insiders are puzzled as to why Japan placed curbs on it in the first place. The general consensus is that Korean firms suffered practically no losses for the past six months since Japan's export control.

[Soundbite] KIM DONG-WON(KB SECURITIES) : "Japan's export controls motivated Korea to develop its own products, thereby helping Korea to gain mid-to-long term competitiveness."

Over the next five years, the Korean government plans to produce locally or diversify import sources for 100 items that are highly dependent on Japan. Subsequently, Seoul will invest more than two trillion won, 2.5 times more than last year, in the materials, parts, and equipment industries this year.

It has been six months since Japan imposed export controls on Korea. Now initially, there were concerns that Korean semiconductor makers would suffer setbacks, but it seems they havn't been hit as badly as it was first thought. Better yet, Japan's export curbs prompted Korea to diversify the country's materials and parts import sources and rely less on Japan.

[Pkg]

Employees in white cleanroom garments are busy conducting a test. They're running the final quality control test to see if the hydrogen fluoride is more than 99.99% pure before it's shipped out. Hydrogen fluoride is one of the three products that were subjected to Japan's export restrictions. It's a key material used in etching silicon wafers and removing impurities from them. Korea depended on Japan to meet two-thirds of its demand as it was more economical. But a Korean hydrogen fluoride manufacturer promptly increased its production lines to successfully replace the Japanese imports with local products in just six months.

[Soundbite] KANG BYEONG-CHANG(CEO, HYDROGEN FLUORIDE MANUFACTURING COMPANY) : "The locally produced hydrogen fluoride received good marks in the quality assessment late last year. Now we can start supplying the products."

Photoresist is an essential material used in engraving semiconductor circuits on silicon wafers. This material caused the greatest concern since it was the item with the highest dependency on Japan and it was projected to take more than a year to develop an alternate product. But contrary to such concern, it was the first material that Korea was able to source elsewhere. The country was able to quickly secure an alternate import source from Belgium. Global corporations are working to produce the material locally. Polyimide used in making flexible displays was not an issue from the beginning since local production had been underway before Japan's export restriction. Industry insiders are puzzled as to why Japan placed curbs on it in the first place. The general consensus is that Korean firms suffered practically no losses for the past six months since Japan's export control.

[Soundbite] KIM DONG-WON(KB SECURITIES) : "Japan's export controls motivated Korea to develop its own products, thereby helping Korea to gain mid-to-long term competitiveness."

Over the next five years, the Korean government plans to produce locally or diversify import sources for 100 items that are highly dependent on Japan. Subsequently, Seoul will invest more than two trillion won, 2.5 times more than last year, in the materials, parts, and equipment industries this year.

이 기사가 좋으셨다면

-

좋아요

0

-

응원해요

0

-

후속 원해요

0

![[HEADLINE]](https://news.kbs.co.kr/data/news/2020/01/06/4356729_10.jpg)

이 기사에 대한 의견을 남겨주세요.