TESTING OF WORLD'S LARGEST CONTAINER CARRIER

입력 2020.05.26 (15:17)

수정 2020.05.26 (16:46)

읽어주기 기능은 크롬기반의

브라우저에서만 사용하실 수 있습니다.

[Anchor Lead]

A Korean shipbuilder recently built the world's largest container carrier. Before handover to the owner, the vessel undergoes a test trial to check on its overall performance. Follow us to the site of the test voyage which marks the first sail and also the last stage in the construction process

[Pkg]

A huge vessel leaves the dockyard and meets the sea for the very first time. As the ship sets sail, tension rises at the upper bridge command center.

[Soundbite] "Emergency training now under way."

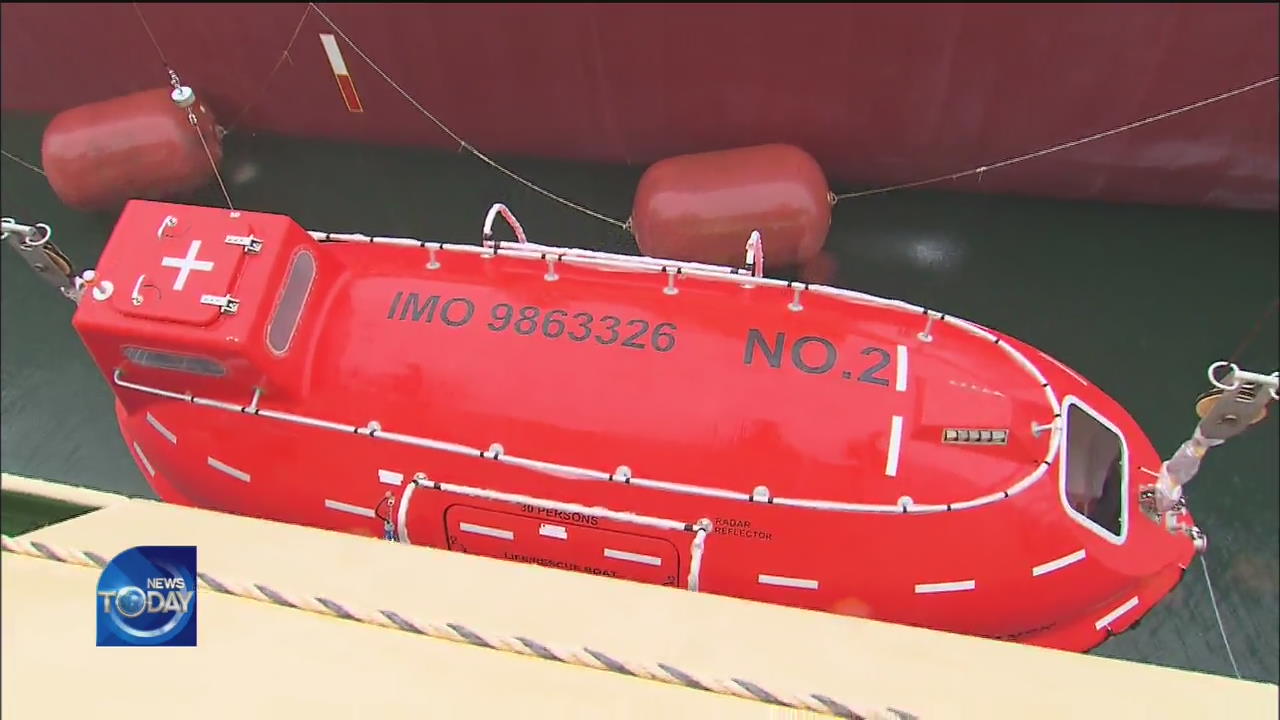

Fire is the most fatal accident that can occur while at sea. It's crucial to inspect whether firefighting equipment, which involves pulling up seawater, is functioning properly. Lifeboats used for evacuation during contingencies are also lowered to check if they are working.

[Soundbite] "Launching, 3, 2, 1!"

The engine room is at the end of a narrow 200 meter hallway. The 11-cylinder, 82,000-horsepower engine is the height of a 3 story building and can generate maximum speed of 22 knots or 40 kilometers per hour. Operational efficiency is a cargo ship's lifeline. This is why the series of tests are held under pressure.

[Soundbite] AN HONG-CHEOL(DSME) : "We are conducting every possible test to verify if they meet the standards and environmental regulations."

Officials climb down dizzying straight ladders. They arrive at the lowest part of the ship, the most difficult part to reach even for crew members. Here, quality tests continue. Even the tiniest mistake will bring about a defect tag. This essential last-stage inspection process is to ensure world-class vessel quality.

[Soundbite] HAN HYO-JOO(HMM TRIAL VOYAGE SUPERVISOR) : "I've been doing nautical supervision work for 12 years. It's an honor to be tasked with inspecting the world's largest container carrier built with Korean technology."

The ship has returned from a 7-day trial operation and will be deployed to a European route starting later this month.

A Korean shipbuilder recently built the world's largest container carrier. Before handover to the owner, the vessel undergoes a test trial to check on its overall performance. Follow us to the site of the test voyage which marks the first sail and also the last stage in the construction process

[Pkg]

A huge vessel leaves the dockyard and meets the sea for the very first time. As the ship sets sail, tension rises at the upper bridge command center.

[Soundbite] "Emergency training now under way."

Fire is the most fatal accident that can occur while at sea. It's crucial to inspect whether firefighting equipment, which involves pulling up seawater, is functioning properly. Lifeboats used for evacuation during contingencies are also lowered to check if they are working.

[Soundbite] "Launching, 3, 2, 1!"

The engine room is at the end of a narrow 200 meter hallway. The 11-cylinder, 82,000-horsepower engine is the height of a 3 story building and can generate maximum speed of 22 knots or 40 kilometers per hour. Operational efficiency is a cargo ship's lifeline. This is why the series of tests are held under pressure.

[Soundbite] AN HONG-CHEOL(DSME) : "We are conducting every possible test to verify if they meet the standards and environmental regulations."

Officials climb down dizzying straight ladders. They arrive at the lowest part of the ship, the most difficult part to reach even for crew members. Here, quality tests continue. Even the tiniest mistake will bring about a defect tag. This essential last-stage inspection process is to ensure world-class vessel quality.

[Soundbite] HAN HYO-JOO(HMM TRIAL VOYAGE SUPERVISOR) : "I've been doing nautical supervision work for 12 years. It's an honor to be tasked with inspecting the world's largest container carrier built with Korean technology."

The ship has returned from a 7-day trial operation and will be deployed to a European route starting later this month.

■ 제보하기

▷ 카카오톡 : 'KBS제보' 검색, 채널 추가

▷ 전화 : 02-781-1234, 4444

▷ 이메일 : kbs1234@kbs.co.kr

▷ 유튜브, 네이버, 카카오에서도 KBS뉴스를 구독해주세요!

- TESTING OF WORLD'S LARGEST CONTAINER CARRIER

-

- 입력 2020-05-26 15:35:35

- 수정2020-05-26 16:46:14

[Anchor Lead]

A Korean shipbuilder recently built the world's largest container carrier. Before handover to the owner, the vessel undergoes a test trial to check on its overall performance. Follow us to the site of the test voyage which marks the first sail and also the last stage in the construction process

[Pkg]

A huge vessel leaves the dockyard and meets the sea for the very first time. As the ship sets sail, tension rises at the upper bridge command center.

[Soundbite] "Emergency training now under way."

Fire is the most fatal accident that can occur while at sea. It's crucial to inspect whether firefighting equipment, which involves pulling up seawater, is functioning properly. Lifeboats used for evacuation during contingencies are also lowered to check if they are working.

[Soundbite] "Launching, 3, 2, 1!"

The engine room is at the end of a narrow 200 meter hallway. The 11-cylinder, 82,000-horsepower engine is the height of a 3 story building and can generate maximum speed of 22 knots or 40 kilometers per hour. Operational efficiency is a cargo ship's lifeline. This is why the series of tests are held under pressure.

[Soundbite] AN HONG-CHEOL(DSME) : "We are conducting every possible test to verify if they meet the standards and environmental regulations."

Officials climb down dizzying straight ladders. They arrive at the lowest part of the ship, the most difficult part to reach even for crew members. Here, quality tests continue. Even the tiniest mistake will bring about a defect tag. This essential last-stage inspection process is to ensure world-class vessel quality.

[Soundbite] HAN HYO-JOO(HMM TRIAL VOYAGE SUPERVISOR) : "I've been doing nautical supervision work for 12 years. It's an honor to be tasked with inspecting the world's largest container carrier built with Korean technology."

The ship has returned from a 7-day trial operation and will be deployed to a European route starting later this month.

A Korean shipbuilder recently built the world's largest container carrier. Before handover to the owner, the vessel undergoes a test trial to check on its overall performance. Follow us to the site of the test voyage which marks the first sail and also the last stage in the construction process

[Pkg]

A huge vessel leaves the dockyard and meets the sea for the very first time. As the ship sets sail, tension rises at the upper bridge command center.

[Soundbite] "Emergency training now under way."

Fire is the most fatal accident that can occur while at sea. It's crucial to inspect whether firefighting equipment, which involves pulling up seawater, is functioning properly. Lifeboats used for evacuation during contingencies are also lowered to check if they are working.

[Soundbite] "Launching, 3, 2, 1!"

The engine room is at the end of a narrow 200 meter hallway. The 11-cylinder, 82,000-horsepower engine is the height of a 3 story building and can generate maximum speed of 22 knots or 40 kilometers per hour. Operational efficiency is a cargo ship's lifeline. This is why the series of tests are held under pressure.

[Soundbite] AN HONG-CHEOL(DSME) : "We are conducting every possible test to verify if they meet the standards and environmental regulations."

Officials climb down dizzying straight ladders. They arrive at the lowest part of the ship, the most difficult part to reach even for crew members. Here, quality tests continue. Even the tiniest mistake will bring about a defect tag. This essential last-stage inspection process is to ensure world-class vessel quality.

[Soundbite] HAN HYO-JOO(HMM TRIAL VOYAGE SUPERVISOR) : "I've been doing nautical supervision work for 12 years. It's an honor to be tasked with inspecting the world's largest container carrier built with Korean technology."

The ship has returned from a 7-day trial operation and will be deployed to a European route starting later this month.

이 기사가 좋으셨다면

-

좋아요

0

-

응원해요

0

-

후속 원해요

0

![[단독] 윤석열 정부, ‘대통령실 공사비 미지급’ 피소](/data/news/2025/06/30/20250630_8MRvHk.png)

이 기사에 대한 의견을 남겨주세요.