TECHNOLOGY TO CREATE ‘STRUCTURAL COLOR’

입력 2021.12.20 (15:09)

수정 2021.12.20 (16:45)

읽어주기 기능은 크롬기반의

브라우저에서만 사용하실 수 있습니다.

[Anchor Lead]

‘Structural Color’ refers to the iridescent pigments only obtained in nature, such as the multicolored plumage of the peacock or mother-of-pearl inlays. Korean scientists have developed a cutting-edge technology that can artificially recreate such brilliant colors.

[Pkg]

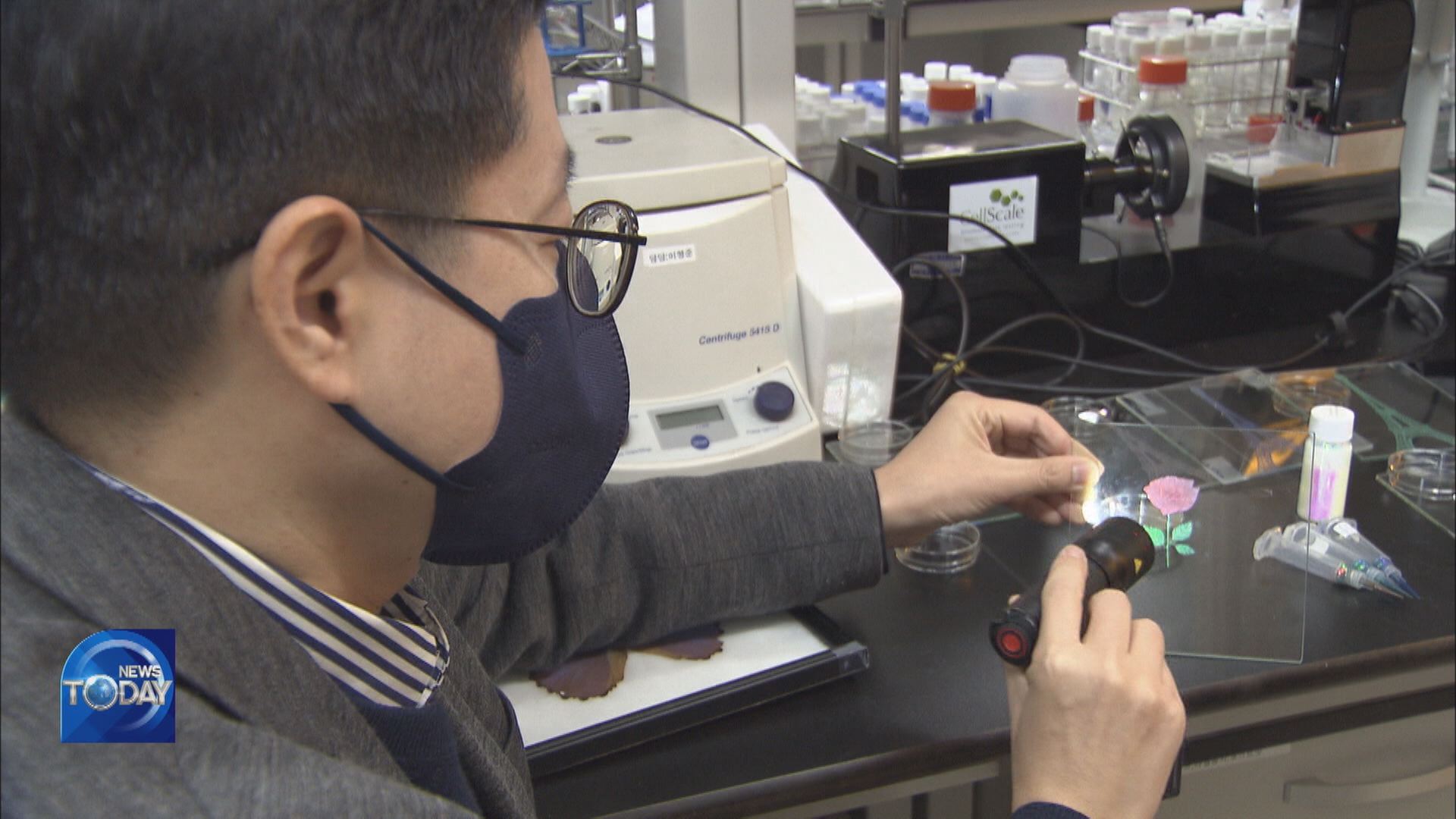

Korean lacquerware inlaid with mother-of-pearl emits iridescent colors only with abalone shells. That is why abalone shells have long been valued as a luxury decorative element. Tail feathers of the peacock are also brilliantly colorful. Such shimmering hues are called “structural colors,” produced by structured surfaces of an object. It was difficult to recreate structural coloration artificially, because iridescence was the result of visible light reflecting off of microscopically structured surfaces in different angles and refractions. A nozzle-type 3D printer sprays a structural color ink on a glass plate and prints the drawing. When the printed drawing is illuminated, it shimmers in red, light green and purple depending on the direction of the light. A team of scientists from KAIST and the Korea Research Institute of Chemical Technology developed this cutting-edge structural color printing technology that uses nano glass bead particles instead of chemical dyes. Microscopic glass bead particles are used to create a 3D crystalline structure to produce a pattern of choice.

[Soundbite] Prof. Kim Shin-hyun(KAIST) : "Since we can make lines as thin as a hair, we can now easily make photonic patterns with high resolution and quality optical characteristics."

The technology is quite versatile as the ink can be printed on non-absorbing surfaces such as glass, metal and plastic as well as on fabric or paper.

[Soundbite] Kim Jong-bin(PhD Candidate, KAIST) : "It’s applicable in various areas such as photonic devices, optical sensors and anti-forgery materials through customized printing techniques."

The latest research was published in the online edition of the journal Science Advances on November 24th before it was applied for patent.

‘Structural Color’ refers to the iridescent pigments only obtained in nature, such as the multicolored plumage of the peacock or mother-of-pearl inlays. Korean scientists have developed a cutting-edge technology that can artificially recreate such brilliant colors.

[Pkg]

Korean lacquerware inlaid with mother-of-pearl emits iridescent colors only with abalone shells. That is why abalone shells have long been valued as a luxury decorative element. Tail feathers of the peacock are also brilliantly colorful. Such shimmering hues are called “structural colors,” produced by structured surfaces of an object. It was difficult to recreate structural coloration artificially, because iridescence was the result of visible light reflecting off of microscopically structured surfaces in different angles and refractions. A nozzle-type 3D printer sprays a structural color ink on a glass plate and prints the drawing. When the printed drawing is illuminated, it shimmers in red, light green and purple depending on the direction of the light. A team of scientists from KAIST and the Korea Research Institute of Chemical Technology developed this cutting-edge structural color printing technology that uses nano glass bead particles instead of chemical dyes. Microscopic glass bead particles are used to create a 3D crystalline structure to produce a pattern of choice.

[Soundbite] Prof. Kim Shin-hyun(KAIST) : "Since we can make lines as thin as a hair, we can now easily make photonic patterns with high resolution and quality optical characteristics."

The technology is quite versatile as the ink can be printed on non-absorbing surfaces such as glass, metal and plastic as well as on fabric or paper.

[Soundbite] Kim Jong-bin(PhD Candidate, KAIST) : "It’s applicable in various areas such as photonic devices, optical sensors and anti-forgery materials through customized printing techniques."

The latest research was published in the online edition of the journal Science Advances on November 24th before it was applied for patent.

■ 제보하기

▷ 카카오톡 : 'KBS제보' 검색, 채널 추가

▷ 전화 : 02-781-1234, 4444

▷ 이메일 : kbs1234@kbs.co.kr

▷ 유튜브, 네이버, 카카오에서도 KBS뉴스를 구독해주세요!

- TECHNOLOGY TO CREATE ‘STRUCTURAL COLOR’

-

- 입력 2021-12-20 15:09:37

- 수정2021-12-20 16:45:07

[Anchor Lead]

‘Structural Color’ refers to the iridescent pigments only obtained in nature, such as the multicolored plumage of the peacock or mother-of-pearl inlays. Korean scientists have developed a cutting-edge technology that can artificially recreate such brilliant colors.

[Pkg]

Korean lacquerware inlaid with mother-of-pearl emits iridescent colors only with abalone shells. That is why abalone shells have long been valued as a luxury decorative element. Tail feathers of the peacock are also brilliantly colorful. Such shimmering hues are called “structural colors,” produced by structured surfaces of an object. It was difficult to recreate structural coloration artificially, because iridescence was the result of visible light reflecting off of microscopically structured surfaces in different angles and refractions. A nozzle-type 3D printer sprays a structural color ink on a glass plate and prints the drawing. When the printed drawing is illuminated, it shimmers in red, light green and purple depending on the direction of the light. A team of scientists from KAIST and the Korea Research Institute of Chemical Technology developed this cutting-edge structural color printing technology that uses nano glass bead particles instead of chemical dyes. Microscopic glass bead particles are used to create a 3D crystalline structure to produce a pattern of choice.

[Soundbite] Prof. Kim Shin-hyun(KAIST) : "Since we can make lines as thin as a hair, we can now easily make photonic patterns with high resolution and quality optical characteristics."

The technology is quite versatile as the ink can be printed on non-absorbing surfaces such as glass, metal and plastic as well as on fabric or paper.

[Soundbite] Kim Jong-bin(PhD Candidate, KAIST) : "It’s applicable in various areas such as photonic devices, optical sensors and anti-forgery materials through customized printing techniques."

The latest research was published in the online edition of the journal Science Advances on November 24th before it was applied for patent.

‘Structural Color’ refers to the iridescent pigments only obtained in nature, such as the multicolored plumage of the peacock or mother-of-pearl inlays. Korean scientists have developed a cutting-edge technology that can artificially recreate such brilliant colors.

[Pkg]

Korean lacquerware inlaid with mother-of-pearl emits iridescent colors only with abalone shells. That is why abalone shells have long been valued as a luxury decorative element. Tail feathers of the peacock are also brilliantly colorful. Such shimmering hues are called “structural colors,” produced by structured surfaces of an object. It was difficult to recreate structural coloration artificially, because iridescence was the result of visible light reflecting off of microscopically structured surfaces in different angles and refractions. A nozzle-type 3D printer sprays a structural color ink on a glass plate and prints the drawing. When the printed drawing is illuminated, it shimmers in red, light green and purple depending on the direction of the light. A team of scientists from KAIST and the Korea Research Institute of Chemical Technology developed this cutting-edge structural color printing technology that uses nano glass bead particles instead of chemical dyes. Microscopic glass bead particles are used to create a 3D crystalline structure to produce a pattern of choice.

[Soundbite] Prof. Kim Shin-hyun(KAIST) : "Since we can make lines as thin as a hair, we can now easily make photonic patterns with high resolution and quality optical characteristics."

The technology is quite versatile as the ink can be printed on non-absorbing surfaces such as glass, metal and plastic as well as on fabric or paper.

[Soundbite] Kim Jong-bin(PhD Candidate, KAIST) : "It’s applicable in various areas such as photonic devices, optical sensors and anti-forgery materials through customized printing techniques."

The latest research was published in the online edition of the journal Science Advances on November 24th before it was applied for patent.

이 기사가 좋으셨다면

-

좋아요

0

-

응원해요

0

-

후속 원해요

0

이 기사에 대한 의견을 남겨주세요.